Field Pilots

India Pilots

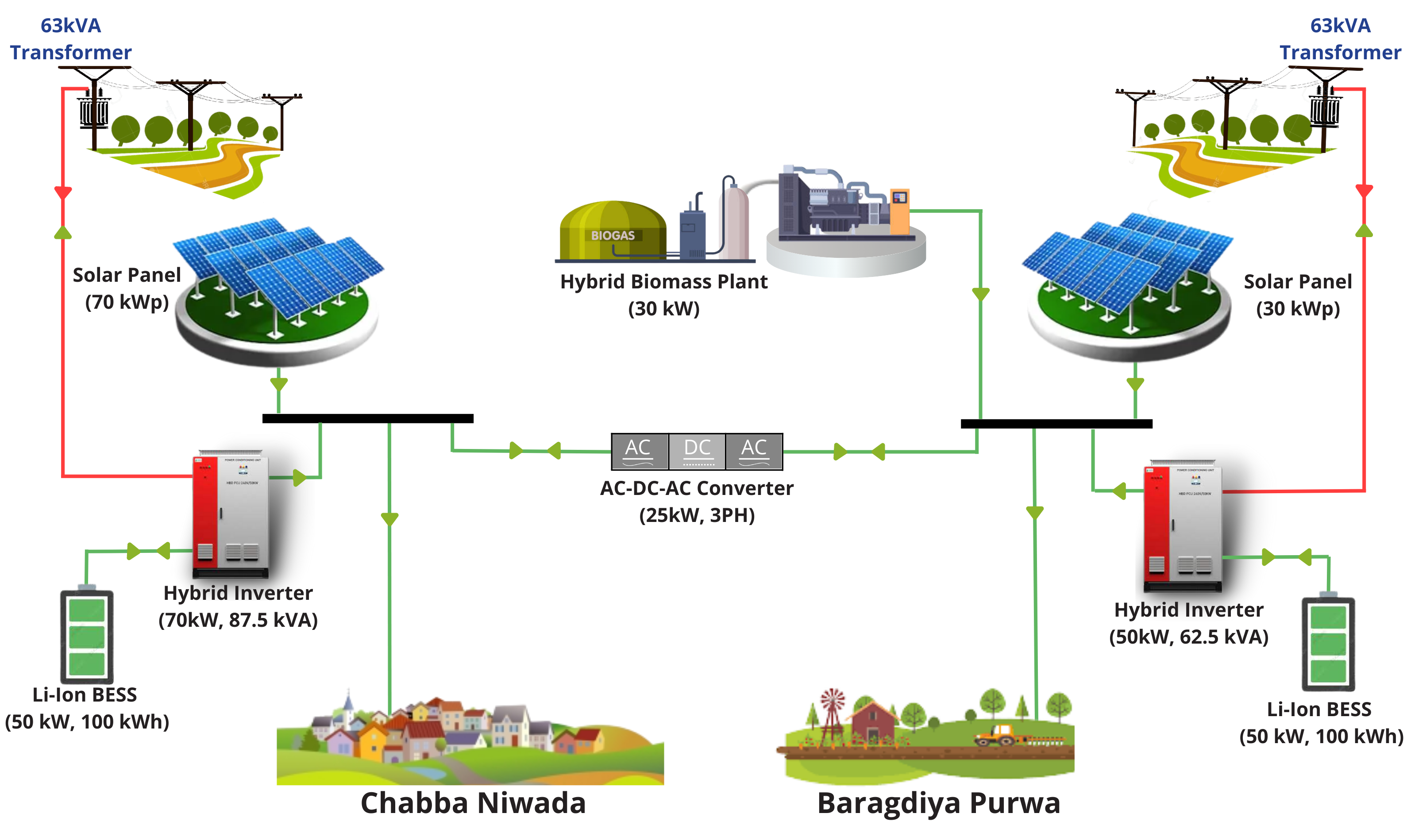

Chhabba Niwada and Bargadiya Purwa village hamlet:

A rural field microgrid scenario has been implemented in the Harnoo village of Kanpur, approximately 40km from the IIT Kanpur campus. Two village hamlets have been selected for the installation of microgrid implementation. In one of the village hamlets, 70 kWp Solar PV, 50 kW & 100 kWh Li-Ion battery energy storage system (BESS), along with a 25 kW AC-DC-AC Converter for power sharing from one village hamlet to another and vice versa, has been installed. In another village hamlet, a 30kW Solar PV, 50 kW & 100 kWh Li-Ion battery energy storage system (BESS), along with a Hybrid Biomass system of 30 kW, has been installed. All houses are also installed with Smart Meters. Different methods are used to utilize the different sources available in the village hamlet to minimize grid import. The installation of standalone solar water pumping stations in village hamlets (3 no.s in each village) provides a sustainable and eco-friendly solution for irrigation, helping to improve agricultural productivity and water resource management in the area.

Chhabba Niwada village hamlet:

- 70kW Solar PV,

- 100kWh BESS with Hybrid Inverter

- 25kW AC-DC-AC converter for power sharing between both village hamlets.

Bargadiya Purwa village hamlet:

- 30kW Solar PV,

- 100kWh BESS with Hybrid Inverter

- 30kW Biomass System utilizing cattle and farm waste.

Other Unique Features of the Rural Pilot

- Six solar pumps for irrigation enhancing agricultural produce.

- Agriculture-based cottage industries for providing local employment.

- Unique community model for managing and operating the rural microgrid.

Status Before Development

- Both village hamlets were un-electrified.

- Transformers and wires to houses provided by utility partner DVVNL with Grid supply being unreliable.

Beneficiaries

- Approx. 700 people of Harnoo village (Two hamlets) are getting benefiting

- Pilot ensures 24x7 reliable supply to Harnoo village.

Challenges

- Sensitizing & involving the local community.

- Getting administrative approvals for the pilot land.

Contact : Shiv Kumar Singh (Email: [email protected]) , Mr. Vinay Kumar Tiwari (Email: [email protected])

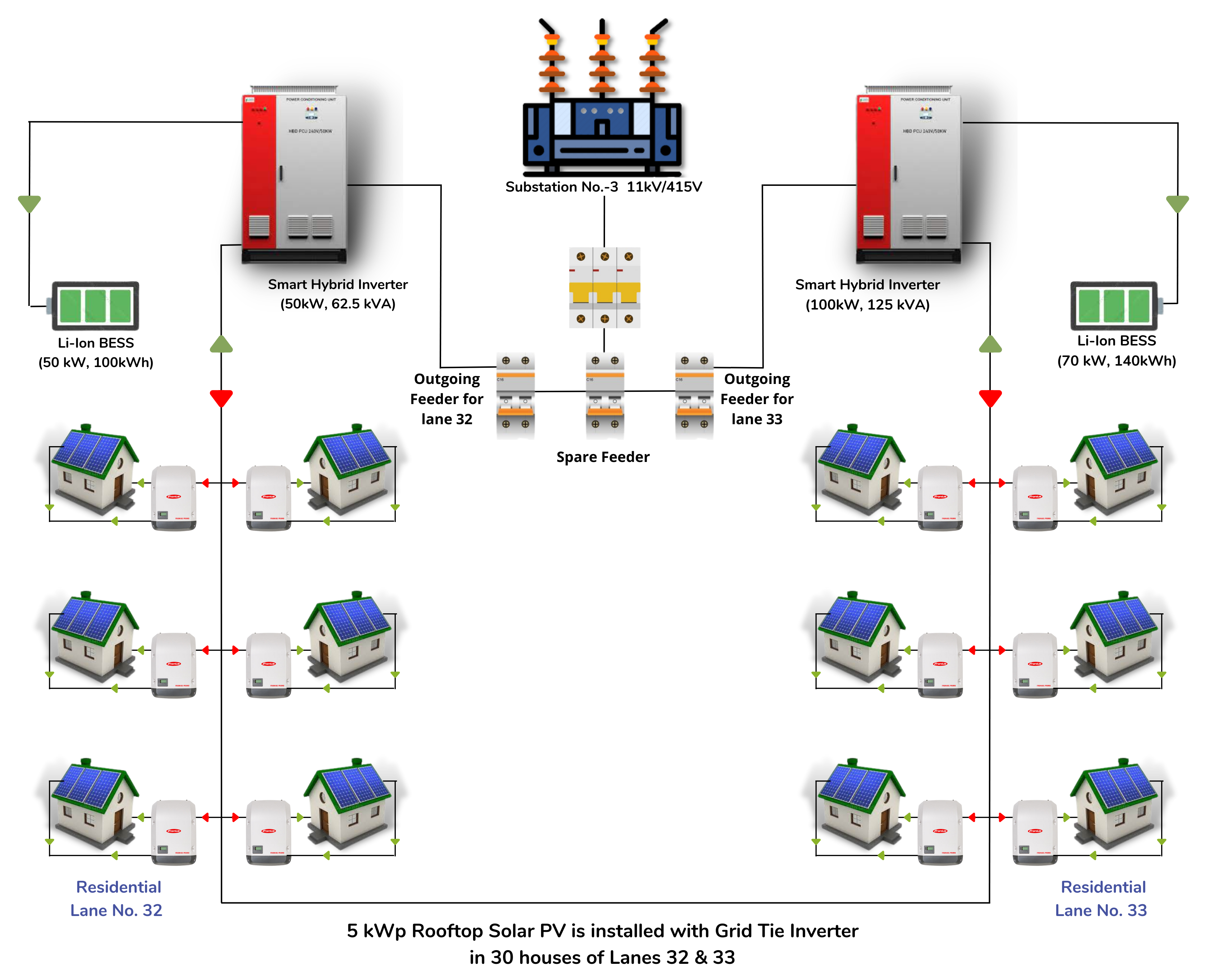

Residential Lane No.(32 & 33) and EV charging stations:

- Out of the 51 houses in lanes 32 and 33, 30 houses were selected based on the shadow analysis survey. All of these 30 selected houses have been equipped with 5kWp Solar PV systems and Smart Meters. Specifically, in lane 32, 12 out of 21 houses have solar PV, while in lane 33, 18 out of 30 houses have solar PV installations.

- Sites for rooftop PV (30 x 5 kWp), centralized storage at two places (140 kWh and 100 kWh Li-ion BESS) in two feeders at the substation.

- Two EV charging stations, each having 50kW DC, 22kW AC, 7.6kW V2H & 3x3.3kW Bharat Chargers integrated with 25kW Solar PV near IIT Kanpur main entrance (gate no 2) and Community Centre.

- Data from smart meters already placed in the two feeders is used for load profiling at the SCADA control centre.

- Operation of the microgrid through the Microgrid Controller.

Contact : Shiv Kumar Singh (Email: [email protected]) , Mr. Vinay Kumar Tiwari (Email: [email protected])

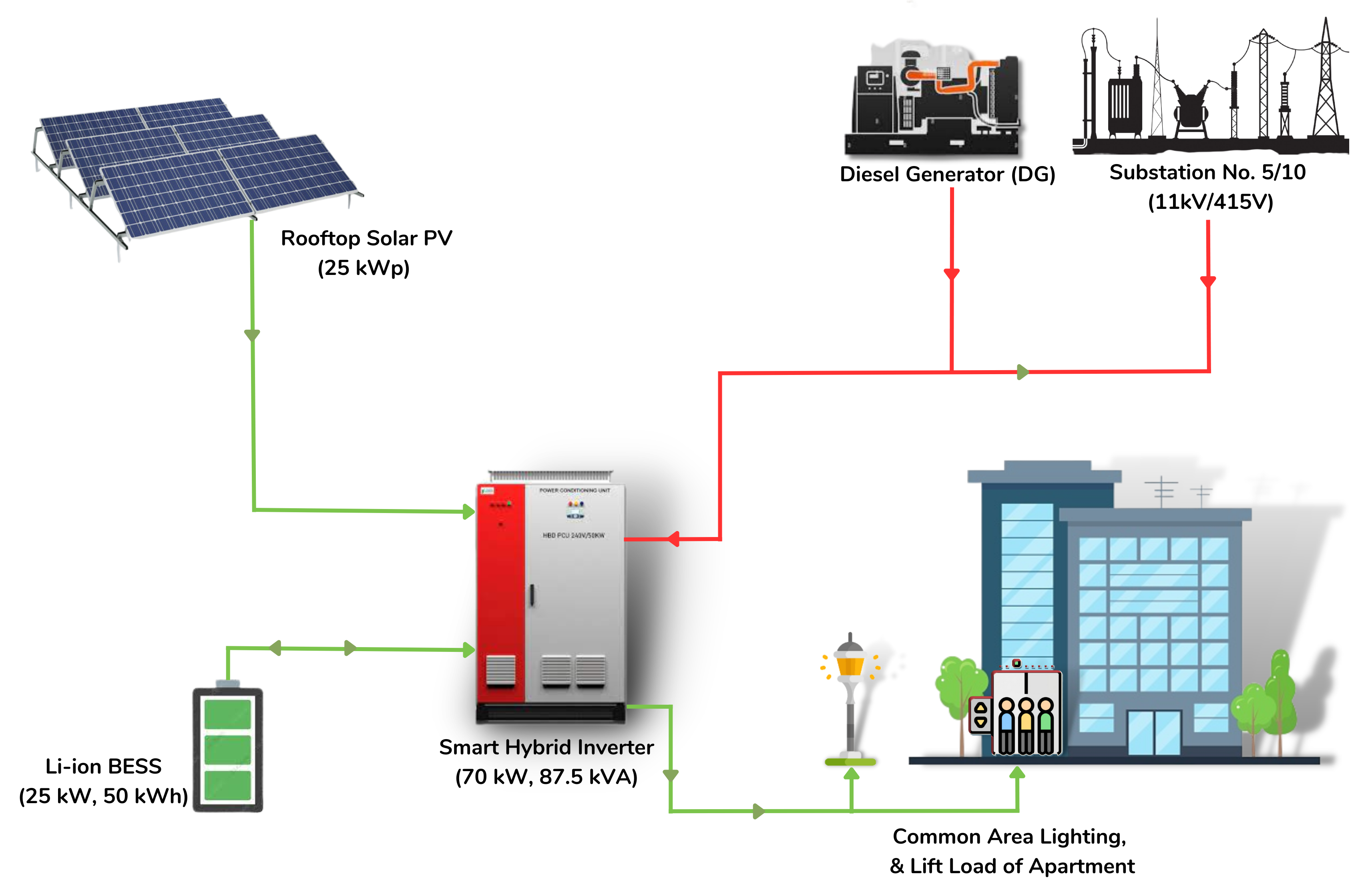

Faculty residence towers C&D.

- Three-phase smart meters, 25kW SPV and Hybrid Inverter along with 50kWh battery are installed in February 2021 at two residential apartments.

- In case of power failure and non-availability of Solar PV output, BESS will feed only common area lighting and lift loads

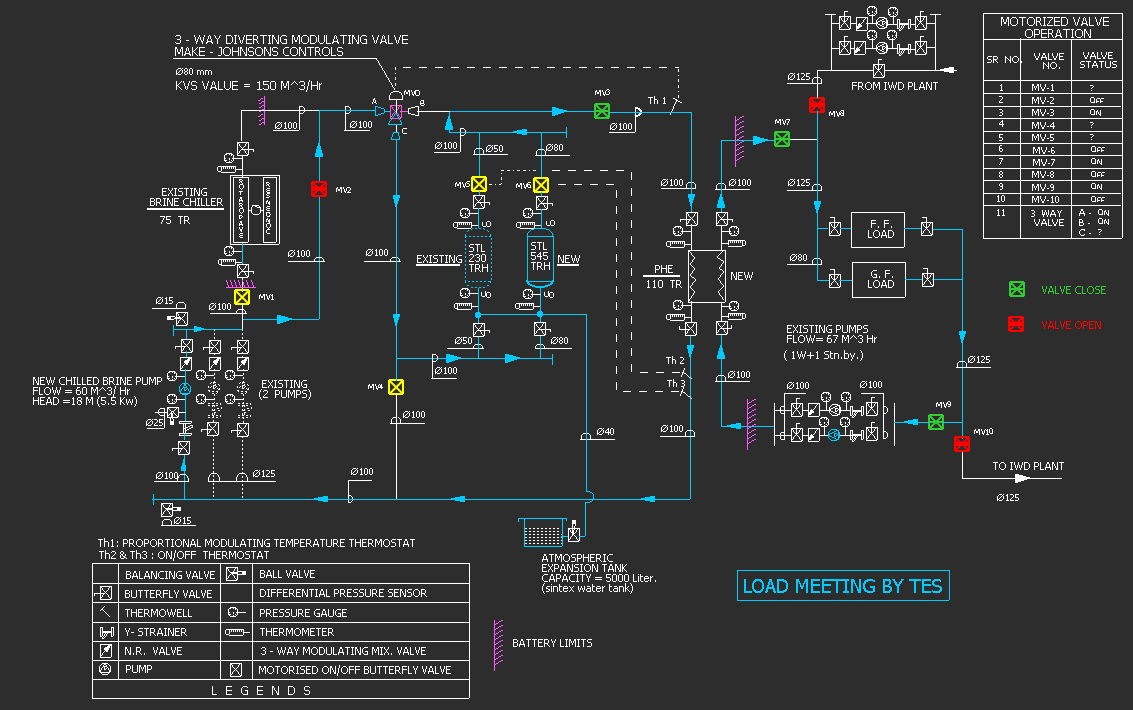

Thermal Energy Storage (TES) System:CESE Building, IIT

Kanpur

- The 545 TRHR TES system has been integrated with the existing 230 TRHR system (made functional in Nov 2020).

- Glycol solution with phase-change material is used for the TES (achieves -4 deg C in about 10 hours).

- During night hours, building AC load shall be met from Institute central AC plant, and during peak load time (11:00 to 17:00 hrs) by the TES system.

- Peak load management by TES system through SCADA system as part of ADMS.

- Integrated with SCADA/ADMS, resulting in peak load reduction.

Contact : Shiv Kumar Singh (Email: [email protected]) , Mr. Vinay Kumar Tiwari (Email: [email protected])

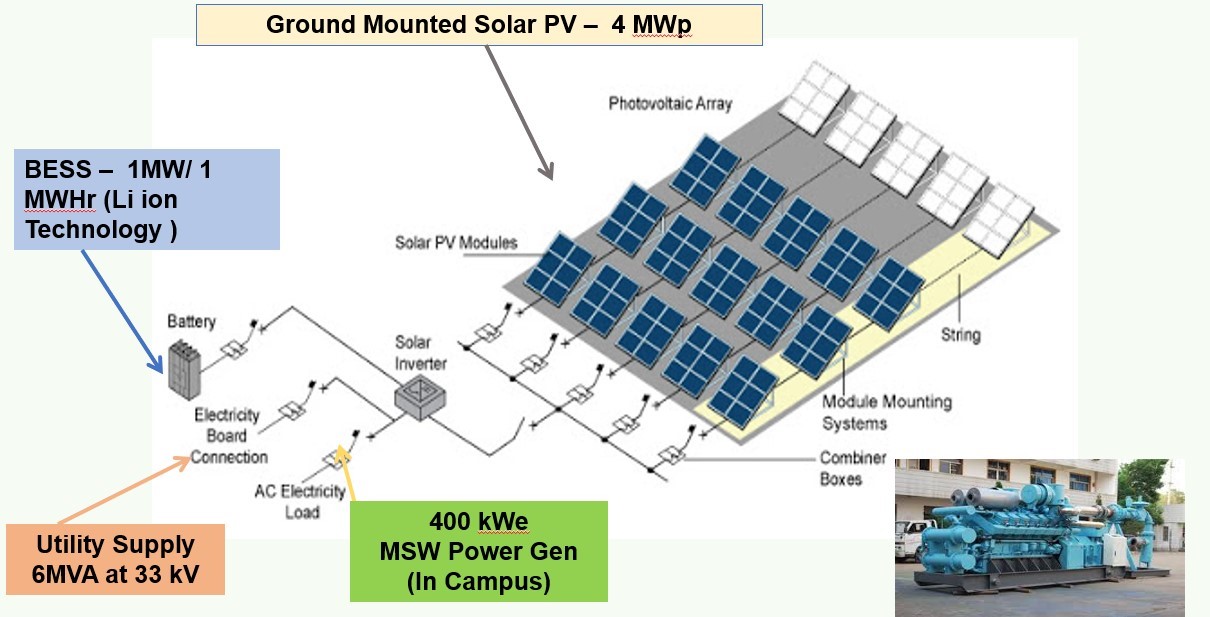

SUB-URBAN FIELD DEMO PILOT BY NETRA

Project: -

Set up of 4MW Ground Mounted Solar Photo Voltaic System with Battery Storage, Load and Source Prioritization with the existing electrical system and Induction based cooking system at NETRA, Greater Noida

Objective: -

In campus generation of electrical power from Solar PV, MSW, DG Set with Battery Energy Storage System and minimum grid support will be taken up.

Salient Features: -

Solar Photo Voltaic Plant: -

4 MW Ground Mounted Solar Photo Voltaic plant to cater the electrical load of NETRA, round the year on the land available in the NETRA campus and connected to the existing electrical network.

Battery Energy Storage System: -

1 MW / 1 MWHr Li ion technology-based BESS to cater emergency load and load during night-time.

Load and Source Prioritization: -

Smart controller to maximize the renewable generation with minimum grid support and prioritize in campus loads (both capacitive and inductive) and different sources (PV, Battery, DG, MSW etc.) for stable electrical system.

Contact :

Ravi Kumar (Email: [email protected])

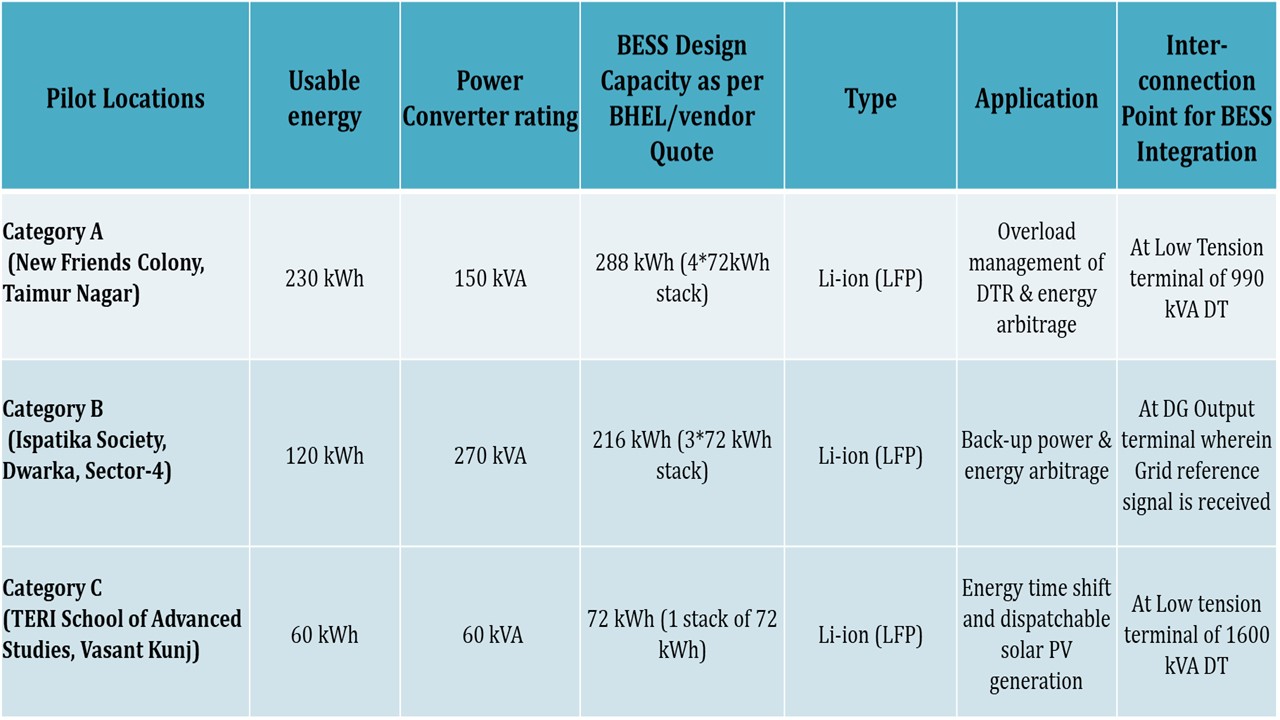

Within BRPL Licensee Area

The Energy and Resources Institute (TERI) in association with partner utility (BSES Rajdhani Power Limited-BRPL) are undertaking the installation of battery energy storage system (BESS) at three different locations within the distribution licensee area of BRPL in NCT of Delhi. The project has been funded Department of Science Technology (DST), Government of India (GoI) under ‘US-India Collaborative for Smart Distribution System with Storage (UI-ASSIST)’.

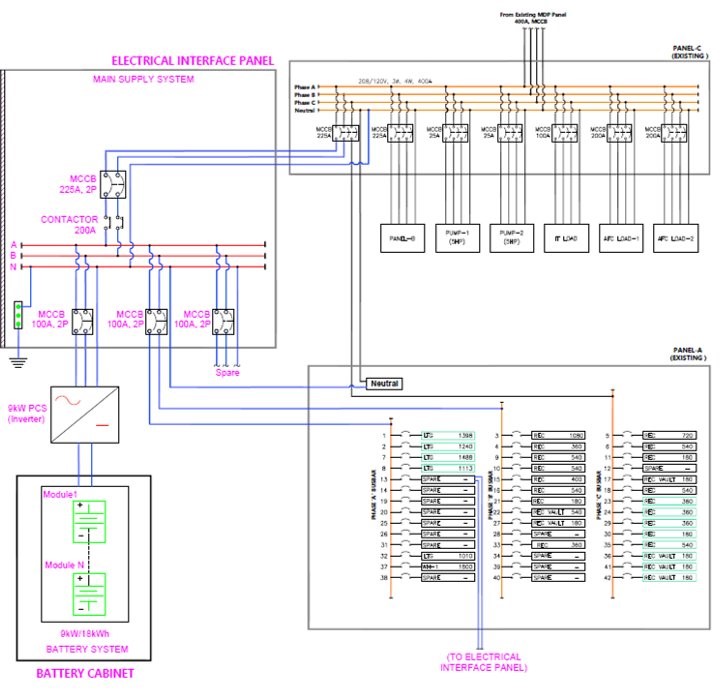

TERI as a research partner has performed the locational planning, sizing of the batteries, tender document preparation, and currently supervising the implementation of BESS. The contract has been awarded to Bharat Heavy Electricals Limited (BHEL), a state owned engineering firm which came out as best supplier during the bidding process. BHEL’s scope of work in the contract includes design, supply, testing, installation & commissioning along with a comprehensive five-year annual maintenance contract (AMC) of the systems at three different locations.

CAT A (Taimoor Nagar):

Technical specifications of BESS:

Overload management of 990 kVA, 11/0.415kV distribution transformer therefor BESS discharging during peak hours and charging during off-peak hours with variable charge/discharge rate.

Secondary application:

Peak power purchase cost saving through energy arbitrage, charging BESS during low-cost period and discharging it during high-cost period for utility perspective.

Technical specifications of BESS:

- Total designed capacity of BESS is 288 kWh having 4 racks of 72 kWh each

- Depth of Discharge: 85%

- PCS rating: 140 kVA

- DC-DC and round-trip efficiency during SAT was 97% & 87% respectively

- Battery chemistry: Lithium Ferro Phosphate (LFP)

- Cell capacity: 100 Ah, 3.2 V

- Interconnection point of BESS low tension (LT) terminal of DT

- Reduce the stress on DT during peak hours

- Investment deferral

- Savings in peak power purchase

- Improved reliability of distribution system while providing uninterrupted power supply to the last mile consumers.

- Increases the DT life

Overload management of 990 kVA, 11/0.415kV distribution transformer therefor BESS discharging during peak hours and charging during off-peak hours with variable charge/discharge rate.

Secondary application:

Peak power purchase cost saving through energy arbitrage, charging BESS during low-cost period and discharging it during high-cost period for utility perspective.

CAT C (TERI SAS):

Technical specifications of BESS:

- Total designed capacity of BESS is 72 kWh having one rack of 72 kWh

- Battery chemistry: Lithium Ferro Phosphate (LFP)

- Cell capacity: 100 Ah, 3.2 V

- Depth of Discharge: 85%

- PCS rating: 60 kVA

- Interconnection point of BESS at LT terminal of 1600 kVA DT

- Saving in consumer electricity bills using time of day (ToD) tariff

- Better utilization of SPV generation and BESS to optimize the battery health

- CO 2 reduction when BESS charging from rooftop SPV (17.3-ton CO 2 /year reduction (as per CEA user guide for CO 2 reduction baseline version 16 Mar 2021), assuming charging of BESS through solar PV and 365 cycles/year

Energy Arbitrage, time of the day (ToD) tariff applicable for May to Sept months and BESS charging/discharging at constant C-rate based on the available energy in battery & duration(s) for charge/discharge.

Secondary application:

Dispatchable solar generation using BESS through Virtual Power Plant (VPP) concept and optimal utilization of distribution energy resources during peak hours. BESS discharging based on solar generation (48kWp rooftop SPV plant installed at site) profile and available energy in battery.